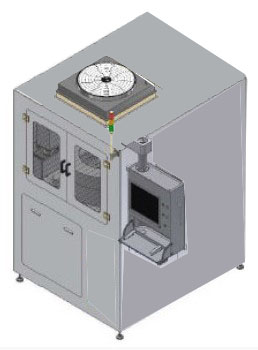

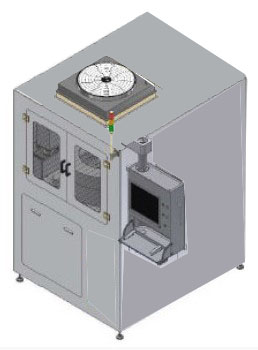

JS-MSC1 Mask Spin Cleaner 마스크 스핀 클리너(글래스 스핀 클리너)

JS-MSC1 JS-MSC1

본 장비는 4인치6인치 또는 그이상의 포토 마스크의 세정및 클리닝 장비 입니다.

JS-MSC1는 브러시 스크러브와 메가소닉 공정을 활용하여 , 고압 스크러브/헹굼 노즐,

다기능 분사 및 세정 노즐을 포함하며 다수의 세척 모듈 장착 가능 합니다.

화학 세정, 린싱 및 스핀 건조 가 가능하고 프로그램을 통해 반복 작동 가능합니다.

|

- 균일하고

높은 세정기능

- 편리한 작동방식

- 회전 PVA 브러시 암

- 스프레이 암

- 메가소닉 암

- 간단한

조작으로 작동 가능

- PLC 소프트웨어 제어

- 다양한 시료 및 마스크 적용

- 고객의 요구에다른 다양한 기능 제공 가능

|

자동형, 반자동형 클린싱 가능 |

미 경

JS-MSC1 |

마스크 스핀 클리너(글래스 스핀 크리너)

-Body Covering: Press Ivory & 투명 PVC

-Plate Size(Max) :100mm X 100 mm glass ~, 사이즈별 주문 제작 가능

-PLC programming ,10 step ,20 memories

-Chamber size: 12 inch

-Substrate Load/Unload: Manual Process

-Brush Arm module:

SUS304 teflon coated, Teflon & PFA Tube

AC Servo Motor 구동: Arm Swing

세정제 Supply Line

D.I Rinsing 용 supply line

Brush Material: PVA, 원형 type

-Spin rotation speed: 100~2000rpm

-Spin Motor: AC Servo Motor System

-Run Time :1~999sec

-Controller: PLC & 10” Touch control panel, Programmable Controller

-1 Megasonic Cleaner

|

세부 규격

1. Main body

1) Dimension (mm): 800x800x1700

2) Frame: SS41 Square pipe frame

3) Body Covering: Press Ivory & 투명 PVC

4) Pipe plumbing: PFA tube & C-PVC, PVC pipe, PP

5) Regulator: Air, N2

6) Drain line: Local line

7) Exhaust Line & Damper

8) Fan filter unit: HEPA filter

9) Controller: PLC & 10” Touch control panel, Programmable Controller

2. Spin Chamber Module

1) Spin Motor: AC Servo Motor System

2) Spin rotation speed: 100~2000rpm

3) Glass Size: 100x 100mm

4) Spin controller: Programmable controller

5) Spin state: 10 steps control Memory

6) Spin Recipe: 20 Recipes Memory

7) Acc/Deceleration rates: variable

8) Chamber size: 12 inch

9) Chamber Material: LDPP 5t

10) Substrate Load/Unload: Manual Process

11) Chuck Material: Teflon coated Al & PTFE block

12) Spin Chuck: 100x 100mm

13) Fan Filter Unit: ULPA Filter, 400x400x125, 1 ea.

14) Brush Arm module: SUS304 teflon coated, Teflon & PFA Tube

AC Servo Motor 구동: Arm Swing

세정제 Supply Line

D.I supply line

Brush Material: PVA, 원형 type

15) Drain: Ø100, 3 port, 배기 겸용

16) Liquid & Vapor separation exhaust tank assembly

3. Local Supply Module

1) 세정제 및 DI nozzle: swing 장착, SUS316 &PTFE

2) N2 nozzle: 상부 & 하부 고정식, SUS316 & PTFE

3) 세정제 Supply System

Chemical Bottle: 1Gallon (3.5L)

Supply: Pumping method

Level sensor

Flow Meter

4) Level Sensor Device Assembly

5) Process Heating system: PID temp control

6) Bottle Cabinet system

7) Bottle Sensor & Flexible Tube

4. megasonic module

1MHz ultrasonic nozzle , Generator

5. Utility

1) Power: 220VAC, 1상, 2Kw

2) N2: 1/4”, 3 kg/cm2 이상

3) DI: VP16A, 2 kg/cm2 이상

4) Air: 1/4”, 4 kg/cm2 이상

5) Drain: VP50A , VP25A

6) Exhaust: VP150A,VP100A

|