- Drying

- Rinse/clean

- Etching

- Manual coating

- Automatic coating

- Developing

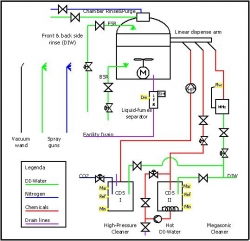

스핀 프로세서 시스템

[장비 사양]

스윙암형(or 리니어암 타입)디스펜서

[Feature]

- Substrate Size(Max.) : 100x100 ~200x200 MM (유저 협의 가능)

- Process step : 10 steps/ program,

- Memory Storage : 10 Programs

- Rotation Speed : 1 ~ 2500 rpm (`5,000 rpm for 6”)

- Acceleration ratio setup, Max. 10000RPM/sec. w/o load

- Run Time : 1~999sec,

[Specification]

- Body structure:Full Plastic

- Bowl :Full Plastic

Size :

Bowl Material : Full Plastic

- Swing Arm(or 리니어암 타입) dispenser

. 온도조절 가능 :0~60C

PR: 압력탱크 공급 방식

현상액: 압력펌프 방식

순수: 사용자 공급조건

Valve: 테프론, PFA

노즐 토출(Dispensing)

노즐: 테프론 또는 PFA 3ea(PR, Developer, DI water)

- Spin Motor, driver:

Rotation Speed: 1 ~ 3,000 rpm (기판 사이즈에 따라 가감 가능)

Spin accuracy: 1RPM @Max. RPM

Spin chuck UP/DOWN

- System Controller: Digital Type, PLC,or 수동형

- Display: LCD Touch Panel or수동 조작

- Accuracy : ±1 RPM

- 내부 LED 조명

- 상측 헤파필터 유닛 :옵션

- Drain:1~ 4 ports

Drain Bottle: PP 18 L

Dispensing nozzle: 1/8”~ 1/4” PFA tube end

Drain full level sensor

- Power Input : 1 phase, AC 220V, 50/60Hz

- Dimension (W X D X H) :

정면 유리 도어

Vacuum Chuck 포함

Alignment tool 포함 (wafer centering tool)

Utility

- Exhaust: 100A, 1 port

- N2: 2~3 Kg/cm2, 3/8” SWGLOK

- CDA: 5 Kg/ cm2 이상

- Electricity: 1 phase, AC 110/220V