POLOS 싱글 웨이퍼 스핀코터 Spincoater Main

미래형 고성능 스핀코터? |

|---|

고성능 , 다기능, 고정밀, 고신뢰성 스핀코터. |

|

모든작업 을 콘트롤 가능한 터치스크린 패널 manufactured in Germany. |

|---|

Clear view of your process

Polos 스핀커터는 R&D 용으로 특별히 설계된 스핀코터 입니다. 4" 프로그램용 디스플레이에서 여러작업을 콘트롤 가능합니다. MEMS, Semi-may require mask cleaning, or a coating step conductor, PV, Microfluidics field, 등등 POLOS 싱글 웨이퍼 스핀코터는수많은 응용작업이 가능합니다. cleaning, rinse/dry, coating, developing and etching. USB 소켓 장착 unlimited메모리 및 스텝 기능 독일제 디지털 서보모터 장착으로 최고의 정밀도 및 신뢰성 요하는 작업 가능. α-crystalline NPP-H 사용으로 일반 NPP보다 100C에서 2배이상의 강도 및 내구성 ,내충격성보유. |

|---|

스핀코터 특징:고속 가속 기능 :up to 0 - 12,000rpm in 0.3 sec. between speed and acceleration Without line break 최대 가속도 :30,000rpm/sec 분리 가능한 터치스크린 콘트롤 패널 - 글로브박스 (glove box)내 설치시 유리. 회전 및 역회전 기능:“puddle” develop and/or etch. Full-Engineering Plastics only, high quality seamless fabrication. 세이프티 록 장착. N2 퍼지포트 장착 :Syringe Holder & Diffuser for N2 외부 관찰 가능한 강화 Glass cover장착 :

depending on substrate size and chuck type |

Benefits

Where the application requires PTFE, we use TFM1600 material, superior for use with chemicals above standard PTFE, with a much higher material surface density than standard PTFE,

thus significantly lower “Memory Capability” for absorbing contamination from Chemicals.

Liners are available in PET (Polyethylenterephthalat), 0.5mm thick, transparent, antistatic (108 - 1010 Ω) to prevent possible build-up of static charge in the chamber.

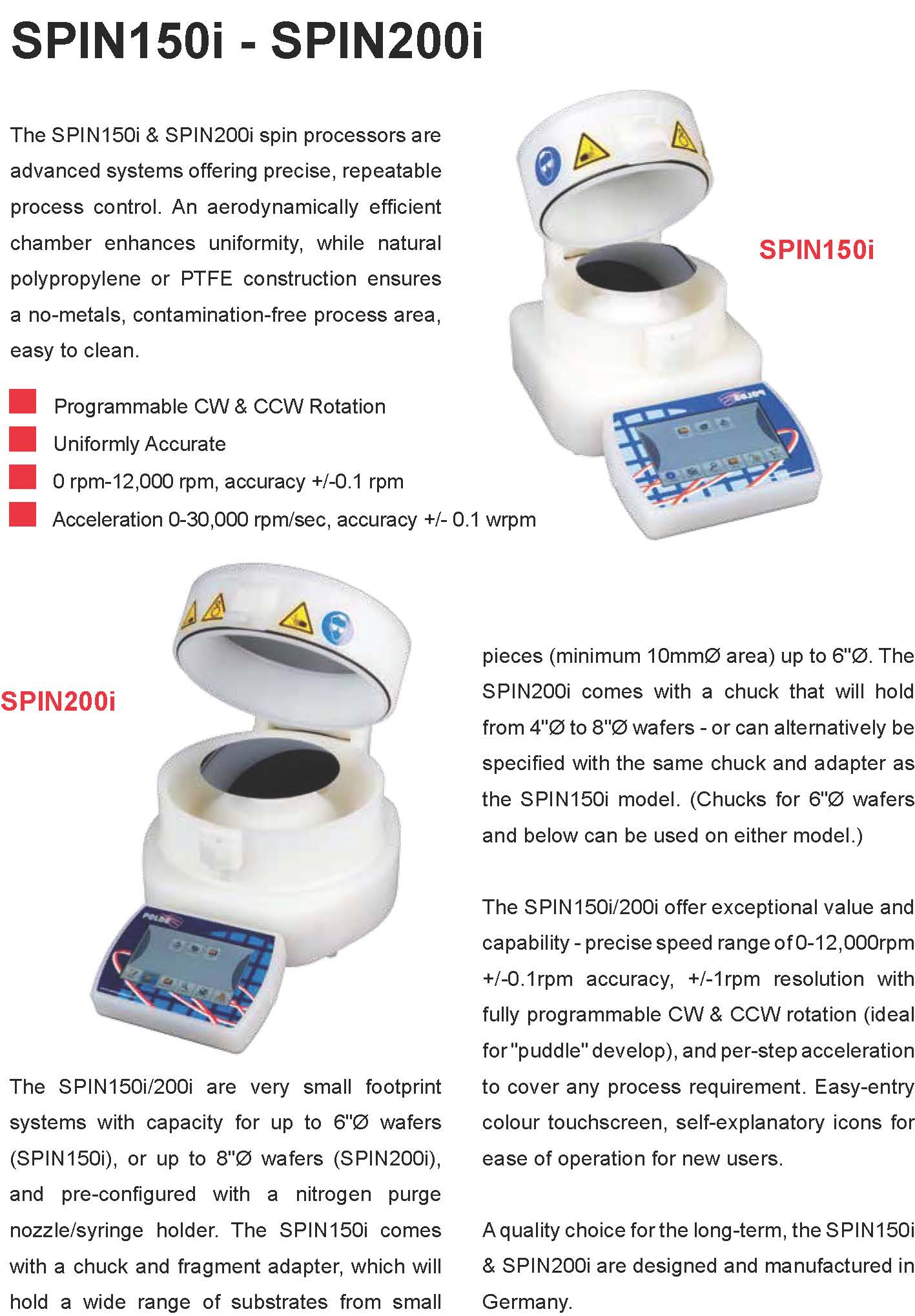

SPIN150i - SPIN200i 스핀코터

| Specifications | SPIN150i | SPIN200i |

|---|---|---|

프로그램수: 스텝: 회전수: 정밀도: 회전방향: |

Unlimited Unlimited 0-12,000 rpm +/-1rpm steps ± 0.1 rpm 정회전,역회전 , Puddle |

Unlimited Unlimited 0-12,000 rpm +/-1rpm steps ± 0.1 rpm 정회전,역회전 , Puddle |

| 최대 가속도:Ramp up down가능 시간 설정 |

30,000 rpm/sec Unlimited , ± 0.1 seconds steps |

30,000 rpm/sec Unlimited, ± 0.1 seconds steps |

| Free programmable outputs: |

3 pcs, relays, nominal switching capacity 0.5A /125 VAC - 0.3A / 60DC |

3 pcs, relays, nominal switching capacity 0,5 A /125 VAC - 0.3A / 60VDC |

시스템 본체 재질: 챔버 재질l: |

Natural Polypropylene (NPP) Natural Polypropylene (NPP) or High Chemical Resistant PTFE (TFM) |

Natural Polypropylene (NPP) Natural Polypropylene (NPP) or High Chemical Resistant PTFE (TFM) |

Interface: External connection: |

Detachable, full-size

touchscreen, glove-friendly, IP52, chemical resistant 1 USB Port in the controller |

Detachable, full-size touchscreen, glove-friendly, IP52, chemical resistant 1 USB Port in the controller |

최대시료 사이즈

:

Max. process chamber diameter: |

160mm round or 4인치 x 4인치 square |

260 mm round or 6인치 x 6인치 square |

| Dimension (desktop version): Shipping weight: Shipping dimension: Requirements Voltage: Power consumption: Max. current: Vacuum: Motor purge gas: Drain connection: |

202 mm 274 (w) x 250 (h) x 451 (d) mm 14 kgs 600 x 380 x 360 mm 100 - 120 VAC / 200 - 240 VAC 50/60 Hz (auto select) Max. 500 W 5A / 2,5A -65 kPa (-19 inchHg), > 80 lpm Tube OD Ø8mm 20 - 50 kPa, 2-5 l/min, Tube OD Ø 6mm 1” M-NPT |

302 mm 380 (w) x 307 (h) x 559 (d) mm 20 kgs 680 x 580 x 480 mm 100 - 120 VAC / 200 - 240 VAC 50/60 Hz (auto select) Max. 500 W 5A / 2,5A -65 kPa (-19 inchHg), > 80 lpm Tube OD Ø8mm 20 - 50 kPa, 2-5 l/min, Tube OD Ø 6mm 1” M-NPT |

Measured without substrate, limitations may apply depending on chuck used and substrate specification

For our spin processors and chucks we use NPP-H with α-crystalline properties..

Options SPIN150i/SPIN200i 스핀코터

|

|

|

|

|---|---|---|---|

|

|

|

|

POLOS Advanced 200 - 300 - 450 스핀코터

|

300mm 300mm |

|---|---|

Polos Advanced series는 디스펜싱 장치를 추가 하는데 좀더 편리합니다. |

Automatic Sequential or Parallel Chemical Dispense Up to 6 spray nozzles Each programmable independently Dispense Vessel (DV), DI Water or N2 |

Specifications POLOS Advanced 스핀코터

| Specifications | POLOS 200 Advanced 스핀코터 | POLOS 300 Advanced 스핀코터 |

|---|---|---|

프로그램수: 스텝: 회전수: 정밀도: 회전방향: 최대 가속도:Ramp up down가능 시간 설정 |

Unlimited Unlimited 1 - 12,000 rpm ± 1rpm steps ± 0.1 rpm Clockwise, Counter clockwise and Puddle 30,000 rpm/sec unlimited |

Unlimited Unlimited 1 - 12,000 rpm ± 1rpm steps ± 0.1 rpm Clockwise, Counter clockwise and Puddle 30,000 rpm/sec unlimited |

Free programmable outputs: |

3 dry relays as standard Up to 16 digital input, 16 digital output, 4 analog input, 4 analog output (with optional IO modules) |

3 dry relays as standard Up to 16 digital input, 16 digital output, 4 analog input, 4 analog output (with optional IO modules) |

| 시스템 본체 재질: 챔버 재질l: |

Natural Polypropylene (NPP) Natural Polypropylene (NPP) or High Chemical Resistant PTFE (TFM) |

Natural Polypropylene (NPP) Natural Polypropylene (NPP) or High Chemical Resistant PTFE (TFM) |

Interface: External connection: |

Detachable, full-size touchscreen, glove-friendly, IP52, chemical resistant 1 USB Port in the controller |

Detachable, full-size touchscreen, glove-friendly, IP52, chemical resistant 1 USB Port in the controller |

최대시료 사이즈

: Max. process chamber diameter: |

260mm round or 6인치 x 6인치 square

|

360mm round or 8인치 x 8인치 square

|

Dimension (desktop version): |

302 mm 380 (w) x 307 (h) x 599 (d) mm |

402 mm 430 (w) x 310 (h) x 650 (d) mm |

Shipping weight: Shipping dimension: |

20 kgs 680 x 580 x 480 mm |

32 kgs 780 (w) x 620 (h) x 580 (d) mm |

Requirements Voltage: Power consumption: Max. current: Vacuum: Motor purge gas: Drain connection: |

100 - 120 VAC / 200 - 240 VAC |

100 - 120 VAC / 200 - 240 VAC |

| Specifications | POLOS 450 Advanced 스핀코터 |

|---|---|

프로그램수: 스텝: 회전수: 정밀도: 회전방향: 최대 가속도:Ramp up down가능 시간 설정 Free programmable outputs: 시스템 본체 재질: 챔버 재질l: Interface: External connection: 최대시료 사이즈 : Max. process chamber diameter: Dimension (desktop version): Shipping weight: Shipping dimension: Requirements Voltage: Power consumption: Max. current: Vacuum: Motor purge gas: Drain connection: |

Unlimited Unlimited 0-1,500 rpm ± 1rpm steps ± 0.1 rpm Clockwise, Counter clockwise and Puddle <1500 rpm/s depends on the load unlimited 3 dry relays, nominal switching capacity 0.5A /125 VAC - 0.3A / 60DC Natural Polypropylene (NPP) Natural Polypropylene (NPP) or High Chemical Resistant PTFE (TFM) Detachable, full-size touchscreen, glove-friendly, IP52, chemical resistant 1 USB Port in the controller 460 round and 350x350mm square substrates 502 mm 795 (w) x 638 (h) x 922 (d) mm 75 kgs 800 x 790 x 1180 mm 200 - 240 VAC 50/60 Hz Peak 1000W 10A -80 kPa (-24 inchHg), > 80 lpm. Tube OD Ø 8mm 20 - 50 kPa. Tube OD Ø 6mm 500lph 1,5” M-NPT |

Considering additional capability of standard unit such as USB backup, recipe cycling, PC software etc.

Measured without substrate, limitations may apply depending on chuck used and substrate specification.

POLOS 200/300/450 Advanced 스핀코터 옵셔널 악세사리

|

|

|---|---|

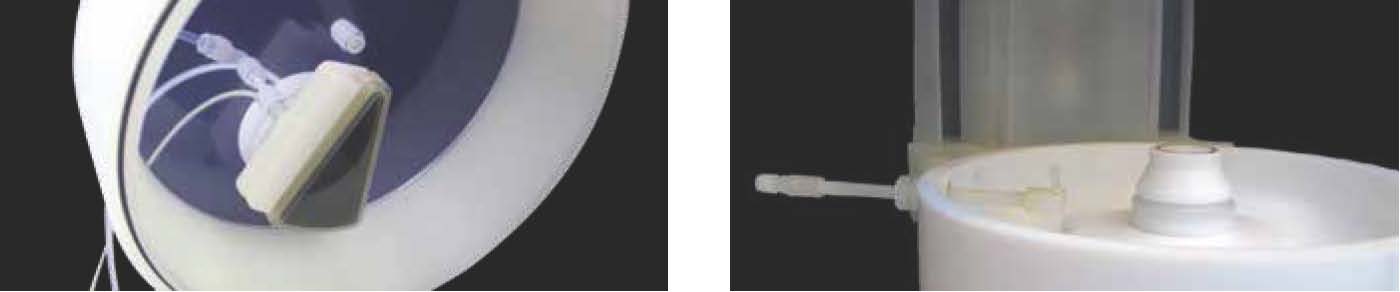

EBR (Edge Bead Removal) Auto Dispense Lines Full PTFE Dispense Vessel Automated injector line |

MegPie BSR (Back Side Rinse) The Sapphire MegPie is a single-wafer Megasonic transducer for cleaning and sonochemical processing. |

|

|

| Static Barrier Plate High Pressure Jet | Corrugated Drainhose, Drain tank andVacuum Pump connector In NPP, including connection to The vacuum pump is very quite and reliable.connect to the drainport. |

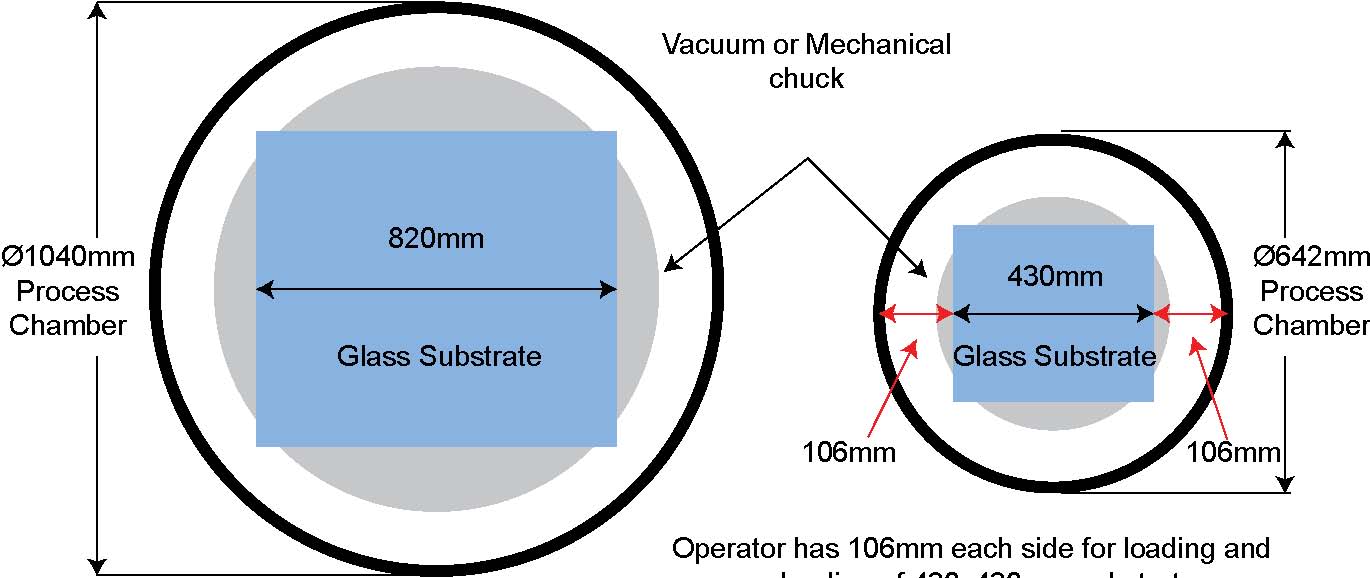

POLOS 600 - 1000 :대형 스핀코터

|

POLOS 1000 NPP POLOS 600 NPP 최대시료사이즈 :642 mm dia |

|---|---|

|

unloading of 430x430mm substrate |

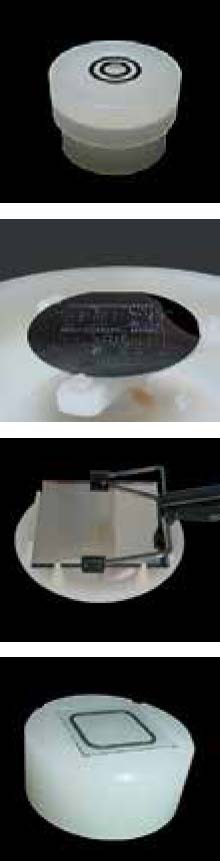

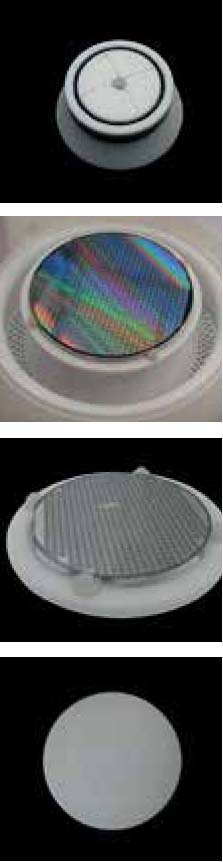

스핀코터용 척(Vacuum or Mechanical Chuck)

- PP or PTFE (solvent safe) chucks공급 가능 최대 300mm.

better film uniformity during coating.

Chucks are available in following materials: PP, PTFE

|

|

|---|

. 척제작은 상담요망